Wednesday, May 29th, 2019

The energy saving potential of atomizing humidifiers with its small horsepower pump unit is well documented but the additional free cooling that occurs during evaporation is often overlooked.

The amount of heat that one pound of water will absorb when changing states from a liquid to a vapor is called its latent heat. This is about 970 BTU/LB at atmospheric pressure with an initial water temperature of 212 deg F. To raise the temperature of water 1 deg F, it takes 1 BTU/LB, known as its specific heat. For example, if you have room temperature water at 70F, it will take 142 BTU’s (212F-70F) plus 970 BTU’s for a total of 1,112 BTU’s to fully evaporate one pound of water by atomizing with a fog system. As you can see, most of the energy is used to change states from a liquid to a vapor and the initial water temperature has minimal effect on the overall cooling.

Thursday, September 6th, 2018

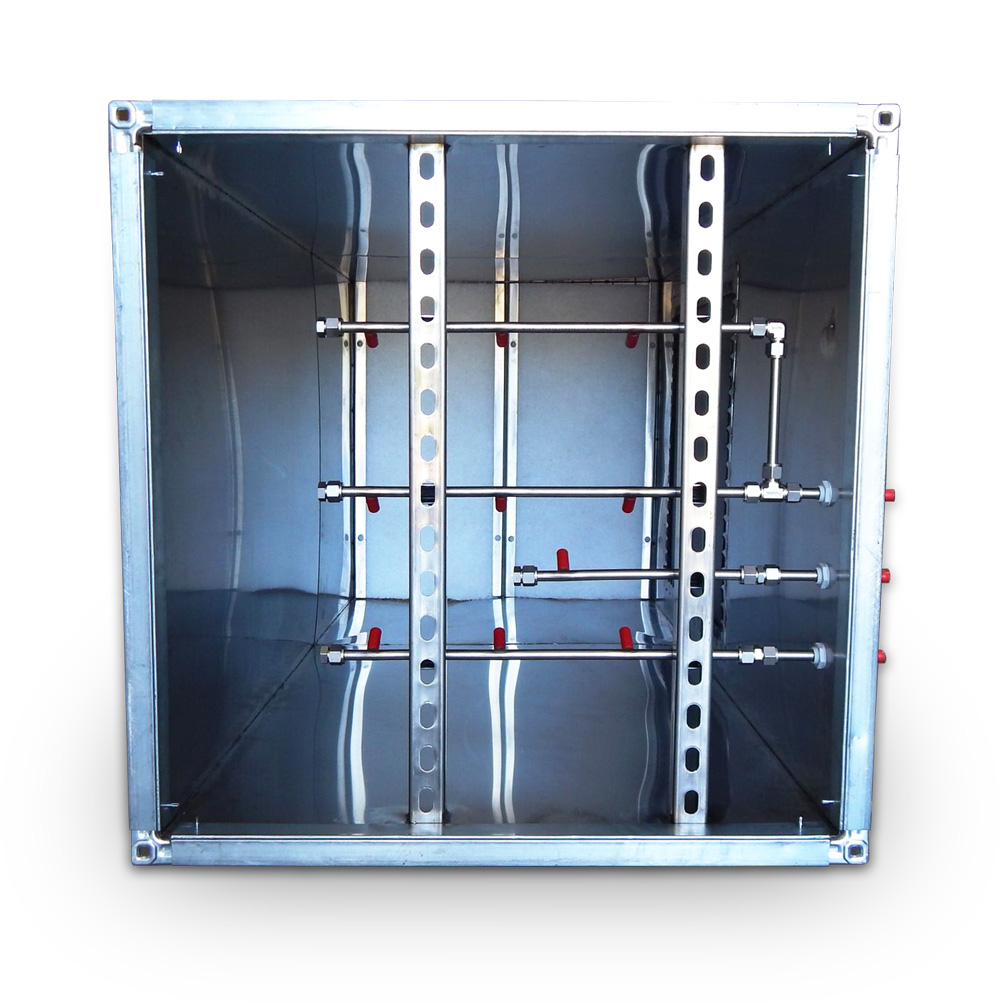

Installing an atomizing humidifier inside of an air handling unit (AHU) can be difficult if there’s not enough room inside the unit for optimal evaporative distance (the distance the atomized water droplets travel from the nozzles to the mist eliminators). Normally, an atomizing humidifier section would require 3-6’ of evaporative distance. So, what do you do if the space just isn’t available?

It’s not as difficult as you might think. You just install the nozzle manifolds and mist eliminators into a modified section of ductwork instead.

Tuesday, November 28th, 2017

GoFog Staging Racks make humidifying inside an AHU easy to control and even easier to install.

The atomizing nozzles installed inside each AHU have an external control panel, with PLC and staging valves, that will modulate the humidifier output based on a BMS demand signal (0-10V or 4-20mA).

The valve rack shown here uses (4) motorized ball valves (3-way) that provide (15) stages of capacity control by sequencing the valves. Attached to each of the valve’s discharge ports are manifolds inside the AHU with varying amounts of nozzles. Once the valve panel receives a BMS demand signal that is high enough to open the first stage, it sends out a pump request to the fog pump station. This provides 1,000 psi of reverse osmosis water to the nozzles.

Tuesday, August 22nd, 2017

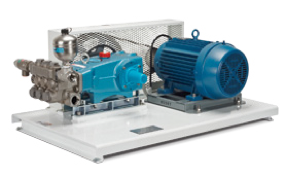

Last month we showed you how to humidify small applications without busting the budget by using our Pico Pump Rack. Here we explain how to properly select a fog pump system for large applications that require thousands of pounds of water per hour.

Monday, July 17th, 2017

As a custom humidifier manufacturer, we understand that humidity loads vary greatly from job to job. For example, some projects may require over 5,000 lbs/hr whereas a small print shop or clean room may only need 100 lbs/hr or less.

These smaller projects can be difficult because the humidity load is too low to justify the cost for a commercial humidifier and too high for a residential humidifier. The Pico Pump Rack bridges this gap without sacrificing quality. All units come with the normal bells and whistles you’ve come to expect (PLC, VFD, CAT Pump), but at a fraction of the size and cost.

Monday, April 24th, 2017

Part 2: Evaporative Cooling Effect

In the second part of this series we explain the positive and negative impacts of evaporative cooling and why it should never be overlooked.

In the second part of this series we explain the positive and negative impacts of evaporative cooling and why it should never be overlooked.

When designing a fog system for a hot dry climate, the evaporative cooling effect is never ignored because it’s an integral part of the design. However, for areas that are typically humid in the summer but need to add humidity during the dry winter months, it can sometimes be an afterthought. If unaccounted for, you may find yourself fighting for control of the HVAC system.

Wednesday, April 19th, 2017

In a nutshell, a Fog System (Atomizing Humidifier) is just high pressure RO water that is atomized through misting nozzles. Seems easy enough, right? While it’s true that these systems are relatively simple, an improper design can have major consequences. In this series, we share with you the most common design mistakes and how to avoid them.

In a nutshell, a Fog System (Atomizing Humidifier) is just high pressure RO water that is atomized through misting nozzles. Seems easy enough, right? While it’s true that these systems are relatively simple, an improper design can have major consequences. In this series, we share with you the most common design mistakes and how to avoid them.

Thursday, January 5th, 2017

High Pressure Fog Systems have been used for decades on a wide variety of projects but there are a few ideal applications where fogging should always be considered.

Monday, October 24th, 2016

Autumn is finally here... open the windows, turn off the A/C and enjoy the fresh cool air. Many non-residential buildings are also enjoying this same benefit by using air-side economizers which allows “free cooling” through the HVAC system.

The benefits are obvious but the lower moisture content in the cool air can make it difficult to maintain humidity levels. Conventional wisdom would assume that adding a steam humidifier to raise the relative humidity would resolve the issue, but since they require approximately 1,000 BTUs of energy to evaporate just 1 lb of water, the energy consumption can potentially offset any savings provided by the economizer. For this reason, many building operators will disable the economizer and mechanically cool the return air instead of running the boiler for humidification. Essentially picking the lesser of two evils and simplifying the sequence of operation.

Tuesday, September 20th, 2016

Using only the highest quality components, GoFog’s Control System meets our demanding requirements but we realize our standards may not always align with yours.

ABB VFD’s not your cup of tea? Not a problem, we regularly use Allen Bradley, Yaskawa, and other major suppliers.